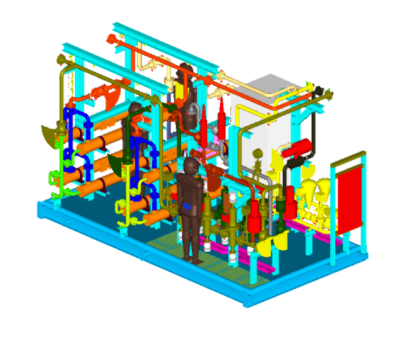

NITROGEN GENERATION

We specialise in nitrogen generation to provide you with reliable and efficient nitrogen supply for a range of industrial applications. Our systems are designed to produce high-purity nitrogen on-site, reducing dependency on external gas suppliers and ensuring a consistent and cost-effective supply. By employing advanced technologies such as pressure swing adsorption (PSA) and membrane separation, we optimise the nitrogen generation process to meet your specific needs and operational requirements. Our solutions focus on maximising efficiency, minimising operational costs, and ensuring that your nitrogen supply is both reliable and scalable. With our expertise in nitrogen generation, we help you maintain smooth operations and achieve your production goals while managing costs effectively.

Technical Specifications

Performance Metrics

Purity Levels: Delivers high-purity nitrogen, typically up to 99.999%, ensuring it meets the stringent requirements for various industrial and laboratory applications.

Flow Rates: Capable of producing nitrogen flow rates from small-scale units of 10 Nm³/h to large-scale systems exceeding 500 Nm³/h, depending on operational needs.

Pressure Ranges: Designed to operate efficiently within pressure ranges of 4 to 10 bar, offering flexibility for different application requirements and ensuring consistent supply.

Energy Efficiency: Utilises advanced technologies to optimise energy consumption, reducing operational costs while maintaining high nitrogen production rates.

Materials Used

High-Grade Adsorbent Media: Features top-quality adsorbent media such as zeolite or activated carbon, ensuring effective separation and high nitrogen purity.

Stainless Steel Components: Constructed with corrosion-resistant stainless steel for all major components, including valves, piping, and storage tanks, ensuring durability and reliability.

Advanced Filtration Systems: Includes high-efficiency filters made from materials such as stainless steel or polymer composites, designed to remove impurities and particulates from the generated nitrogen.

Control Systems: Equipped with state-of-the-art control systems and sensors, including PLCs and touch-screen interfaces, for precise operation and monitoring of nitrogen generation.

Applicable Environments

Industrial Facilities: Ideal for various industrial applications where a steady supply of high-purity nitrogen is required for processes such as blanketing, purging, and inerting.

Oil and Gas: Effective in the oil and gas sector for applications such as enhanced oil recovery and inerting during maintenance operations.