N₂ REMOVAL

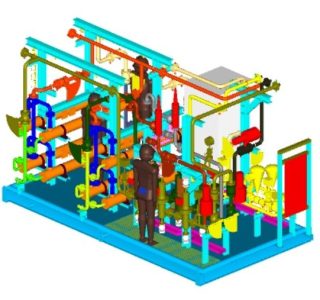

Effectively managing nitrogen (N₂) levels in natural gas and hydrocarbon streams is essential for improving gas quality and increasing its energy content. Our N₂ removal systems are tailored to efficiently separate and lower nitrogen concentrations, ensuring that your gas meets required specifications for downstream use. We employ cutting-edge cryogenic distillation and membrane technologies, which allow for accurate and efficient nitrogen extraction. By optimising these processes, our solutions help you achieve better product quality, meet industry standards, and enhance the overall value of your gas, all while maintaining operational efficiency.

Technical Specifications

Performance Metrics

Removal Efficiency: Achieves up to 99% efficiency in removing nitrogen (N₂) from natural gas and other gas streams, ensuring the final product meets pipeline and commercial quality standards.

Flow Rates: Capable of processing gas flow rates from 1,000 to 100,000 standard cubic feet per minute (SCFM), suitable for both small-scale and large-scale operations.

Operating Pressure: Functions effectively under a wide range of pressures, typically from 10 to 150 bar, allowing for seamless integration with existing gas processing facilities.

Product Purity: Ensures high-purity output, with methane recovery rates often exceeding 95%, making the system ideal for applications where gas quality is critical.

Materials Used

Membrane Systems: Utilises high-performance membrane systems made from advanced polymeric materials, specifically designed for selective nitrogen permeation and separation.

Cryogenic Distillation Units: Incorporates cryogenic distillation units constructed from stainless steel or aluminium, enabling efficient nitrogen removal at low temperatures.

Absorption Towers: Built with corrosion-resistant materials like stainless steel or specialised alloys, these towers facilitate the effective absorption and removal of nitrogen.

Precision Control Systems: Equipped with state-of-the-art control systems made from durable materials, ensuring precise management of gas flows, pressures, and temperatures.

Applicable Environments

Natural Gas Processing Plants: Ideal for natural gas processing facilities where nitrogen removal is essential to meet pipeline specifications and improve the heating value of the gas.

LNG and LPG Facilities: Suitable for LNG (Liquefied Natural Gas) and LPG (Liquefied Petroleum Gas) production facilities, where the removal of nitrogen is critical to achieving the desired product composition.

Industrial Gas Applications: Applicable in industries that require nitrogen-free gases, such as in chemical manufacturing, where pure methane or other hydrocarbons are needed.

Enhanced Oil Recovery (EOR) Operations: Beneficial for Enhanced Oil Recovery projects, where nitrogen must be separated from gas streams to optimise the injection process and improve oil recovery rates.