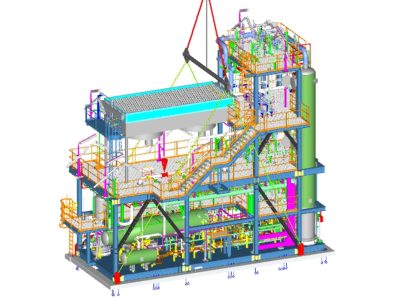

MEG REGENERATION

We specialise in maintaining the integrity and efficiency of natural gas processing through our expertise in MEG (Monoethylene Glycol) regeneration. MEG is crucial for preventing hydrate formation in gas pipelines, particularly in offshore environments. Our advanced regeneration techniques effectively remove water and salts from the used MEG, restoring its concentration and purity for continuous reuse. This not only minimises operational costs but also ensures the smooth flow of gas and protects your infrastructure from corrosion and blockages. With our cutting-edge solutions, your gas processing operations remain reliable, cost-effective, and aligned with industry best practices.

Technical Specifications

Performance Metrics

Glycol Recovery Rate: Efficiently recovers up to 98% of MEG, minimising waste and maximising cost-effectiveness.

Flow Rates: Supports a wide range of flow rates, from 0.5 to 50 MMSCFD, ensuring adaptability to various processing needs.

Salt Removal Efficiency: Removes salts and other contaminants to achieve purity levels exceeding 99%, ensuring high-quality glycol recovery.

Pressure Levels: Operates effectively within pressure ranges of 500 to 1500 psi, optimising system performance.

Materials Used

Heat Exchangers: High-grade stainless steel construction to resist corrosion and ensure long-term durability in glycol processing environments.

Reboilers: Constructed from carbon steel with internal stainless steel components to handle high-temperature operations efficiently.

Filtration Systems: Utilises advanced polymeric and ceramic filters to enhance the purity of regenerated glycol, prolonging system life.

Piping and Valves: Made from corrosion-resistant alloys, ensuring reliable operation in harsh processing environments.

Applicable Environments

Offshore Platforms: Tailored for the demanding conditions of offshore platforms, including exposure to saltwater, high winds, and temperature fluctuations.

Subsea Operations: Suitable for subsea tiebacks, providing reliable MEG regeneration for hydrate management in deepwater operations.

High-Salinity Areas: Specifically designed to perform in high-salinity environments, effectively managing salt deposition and scaling issues.

Onshore Processing Facilities: Ideal for onshore gas processing plants, ensuring efficient and continuous MEG regeneration even under heavy operational loads.