WATER FLOODING

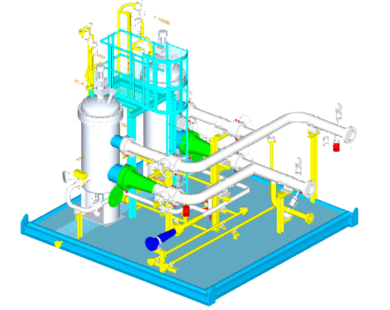

Water flooding is a critical enhanced oil recovery technique used to maintain reservoir pressure and boost oil production. Our water flooding systems are designed to efficiently inject water into oil reservoirs, displacing oil and driving it towards production wells. By employing advanced pump and filtration technologies, we ensure that the injected water is free of impurities and delivered at the optimal pressure, maximising oil recovery while protecting reservoir integrity. These systems are essential for extending the life of your oil fields, improving production rates, and enhancing the overall efficiency of your operations, leading to more sustainable and cost-effective oil extraction.

Technical Specifications

Performance Metrics

Injection Efficiency: Achieves high water injection rates, typically ranging from 10,000 to 150,000 barrels per day (BPD), optimising reservoir pressure maintenance and enhancing oil recovery.

Pressure Control: Designed to operate under various injection pressures, typically up to 300 bar, ensuring precise control over injection rates to maximise sweep efficiency and minimise the risk of reservoir damage.

Water Quality Management: Ensures consistent water quality with filtration and treatment systems capable of reducing suspended solids to below 2 microns, preventing formation plugging and enhancing injectivity.

Operational Uptime: Engineered for continuous operation with over 98% uptime, minimising downtime and ensuring sustained reservoir pressure to support ongoing production activities.

Materials Used

Corrosion-Resistant Injection Pumps: Utilises high-performance injection pumps constructed from stainless steel or duplex steel, ensuring durability and resistance to corrosion from saline or produced water.

Filtration and Treatment Units: Features advanced filtration systems and chemical treatment units made from robust materials such as titanium or high-grade polymers, designed to remove particulates and dissolved gases from injection water.

Pipeline and Piping Systems: Constructed from corrosion-resistant alloys like 316 stainless steel or coated carbon steel, ensuring longevity and reliability in transporting water from treatment facilities to injection wells.

Control and Monitoring Systems: Equipped with state-of-the-art control systems, including programmable logic controllers (PLCs) and remote monitoring capabilities, ensuring precise control over injection rates and real-time data tracking.

Applicable Environments

Offshore Oil Fields: Ideal for offshore oil fields where maintaining reservoir pressure is critical to sustaining production rates, especially in mature fields nearing the end of primary recovery.

Onshore Waterflood Projects: Suitable for onshore waterflood projects, where large-scale water injection is required to enhance oil recovery and extend